zwick pendulum impact tester|pendulum impact tester : agent ZwickRoell‘s HIT range of pendulum impact testers are available from 5 to 50 joules and offer a solution combining high precision with cost-effectiveness. “4-3-2-1” is how ZwickRoell . WEB14.7k 40sec - 1080p. Nath Cardz. Morena Casada Saiu com o Amante e Acabou Gozando Muito e Teve o Primeiro SQUIRT! 112.7k 100% 21min - 1080p. Ksalab. Fudendo com .

{plog:ftitle_list}

webTriz Pariz photos & videos. EroMe is the best place to share your erotic pics and porn videos. Every day, thousands of people use EroMe to enjoy free photos and videos. .

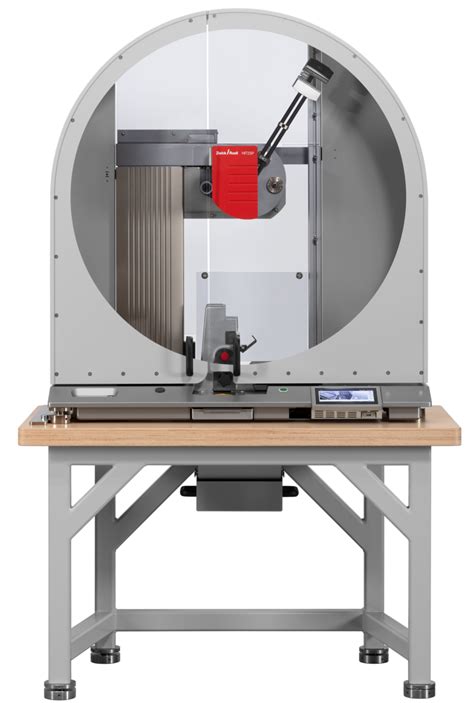

With our HIT series pendulum impact testers for tests on plastics up to 50 joules, ZwickRoell offers a particularly precise, while also economical solution for the polymer industry: Charpy .

ZwickRoell’s HIT series pendulum impact testers offer a high-precision, cost .Our product line includes pendulum impact testers for metals and pendulum impact .ZwickRoell’s HIT series pendulum impact testers offer a high-precision, cost effective solution. Pendulum impact test on plastics. Standard-compliant testing according to Charpy, Dynstat, .

ZwickRoell‘s HIT range of pendulum impact testers are available from 5 to 50 joules and offer a solution combining high precision with cost-effectiveness. “4-3-2-1” is how ZwickRoell .

Its product line includes pendulum impact testers for metals and plastics, drop weight testers with an energy range of only a few joules to 100,000 Joules, as well as high-speed testing machines. All ZwickRoell pendulum impact .The specimen is screwed into the impact tensile pendulum head. The free end of the specimen is bolted to the yoke. During the test the yoke impacts the impact tensile anvil. Description Item number Equipment for impact tensile tests Consists of 300-joule impact tensile pendulum head and installation accessories. 940418 Product Information . Impact tests are one of the most frequently performed mechanical tests in the polymer industry. ZwickRoell's HIT range of pendulum impact testers are availab.

In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the point at which the pendulum hammer strikes the specimen. This impact test is used to determine the absorbed impact energy.The Pendulum Impact Testers from Zwick are a HIT Important Characteristics Leading mechanical testing products manufacturer Zwick Roell Group’s HIT Pendulum Impact Testers are benchmark instruments for plastics manufacturers and processors Accuracy, dependability and ergonomic design are primary features of the HIT pendulum impact testers. .

Impact testers help determine the failure behavior of materials or components under rapid loads and changing temperatures. The ZwickRoell product line includes pendulum impact testers for metals and plastics and drop weight testers with an energy range of .

HIT750P pendulum impact tester 2510 2773 2273 500 2000 2361 2556 1100 743 Pendulum impact tester HIT750P, dimensions Applications The HIT750P can be used for tests to the following standards: ISO 148-1, ISO 14556, ASTM E23, JIS Z 2242, GOST 9454-78, DIN 50115 (withdrawn). • Impact bending tests on metals (Charpy, conventional and instrumented)The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .HIT Pendulum impact tester secara otomatis mengidentifikasi pendulum yang digunakan, memastikan bahwa nilai yang diukur selalu ditentukan dalam kisaran yang benar dan sesuai dengan standar yang digunakan. Pertama di dunia adalah penggunaan batang ganda karbon untuk pendulum. Ini memberikan tingkat kekakuan yang tinggi dalam arah impact dan .1. The Pendulum Impact Testers from Zwick are a HIT Important Characteristics Leading mechanical testing products manufacturer Zwick Roell Group’s HIT Pendulum Impact Testers are benchmark instruments for plastics manufacturers and processors Accuracy, dependability and ergonomic design are primary features of the HIT pendulum impact testers.

The RKP 450 Pendulum Impact Tester is ideally designed and created to provide an excellent quality performance and functionality for very specific purposes. It is a pendulum impact tester which may be used for Charpy, Izod, Brugger, impact tensile and wedge impact tests which is basically compliant to the DIN, EN, ASTM, ISO and BS standards.

zwickroell pendulum

The name "pendulum impact tester" is self-explanatory for the operation of the machine. A lifted mass has potential energy. This is converted to kinetic energy by the mass being exposed to a free fall. . Zwick pendulum impact testers in the RKP 450 range meet the requirements of EC Machinery Directive 2006/42/EC and of EN ISO 12100 and EN ISO .

Pendulum impact testers for tests on plastics Up to 50 joules Industries • - Predominantly plastics Max. energy • - 50 joules Type of test • - Charpy • - Izod • - Dynstat • - Impact tensile Pendulum Impact Testers for Plastics Testing – Accurate, Reliable and Operator-Friendly Together with tensile and flexure tests, Charpy impact tests are the most frequently performed . The HIT750P can be used for tests to the following standards: ISO 148-1, ISO 14556, ASTM E23, JIS Z 2242, GOST 9454-78, DIN 50115 (withdrawn).• Impact bendin.For automated impact tests (Charpy/Izod) Industries • - Plastics Type of test • - Impact flexure (Charpy, Izod) Specimen range • - Cooled specimens Standards • - ISO 179-1 • - ISO180 • - ASTM D256 • - ISO 148-1 • - ASTM E23 The robotic .

Safety device Zwick pendulum impact testers in size category PSW 750 satisfy the EC Machinery Directive 2006/42/EC, the EN ISO 12100 as well as the EN ISO 13849-1/2. This means that the failure of a single safety monitoring element must not pose any risk to the operator. The design of the safety housing facilitates easy handling during the .

Zwick 5113 Pendulum impact tester (basic model with analogue display and 160° deflection) Note: not to be used for tests with impact velocities of v=3,4 m/s, e.g. DIN EN ISO 180 and ASTM D 6110-97 (previously ASTM D 256-97)1. The latest Pendulum Impact Testers from Zwick are a HIT Important Characteristics As a leading producer of mechanical testing products, the Zwick Roell Group’s HIT pendulum impact testers are powerful instruments for plastic manufacturers and processors. The main characteristics of the HIT pendulum impactHIT750P pendulum impact tester 2510 2773 2273 500 2000 2361 2556 1100 743 Pendulum impact tester HIT750P, dimensions Applications The HIT750P can be used for tests to the following standards: ISO 148-1, ISO 14556, ASTM E23, JIS Z 2242, GOST 9454-78, DIN 50115 (withdrawn). • Impact bending tests on metals (Charpy, conventional and instrumented)Zwick pendulum impact testers in size category RKP 450 satisfy the EC Machinery Directive 2006/42/EC, the EN ISO 12100 as well as the EN ISO 13849-1/2. This means that the failure of a single safety monitoring element must not pose any risk to the operator. As a

Pendulum impact testers determine the impact energy absorbed by a standardized specimen up to break by measuring the height of rise of the pendulum hammer after impact. The result is impact strength or notched impact strength, which is indicated in relation to area, for example in kJ/m². We will give an overview of the standard test methods .Robotic Testing System ‘roboTest I’ (Impact) for pendulum impact testers PI486_roboTest_I.pmd PI486 2.0609 Robotic testing system ‘roboTest I’ for pendulum impact tester RKP 450 or PSW 750 Application The robotic testing system is used for semi or fully automatic tempering, feeding and testing of Charpy specimen according to EN10 045 or .Product Information Pendulum Impact Tester PSW 750 Installation According to international Standards, the base frame should be firmly anchored to the floor. . Rebound resilience tester Zwick 5109. 2 Pages. Creep Testing Kappa SS. 4 Pages. Mflow Extrusion Plastometers. 4 Pages. Electro-Mechanical Materials Testing Machines 330 kN.

Our materials testing machines are used in R&D and for quality assurance in more than 20 industries. . Mohr & Federhaff, and Roell and Zwick have been inseparably associated with the materials testing industry. As a private company, we always keep this tradition in mind and use . Flexure Test ISO 178; Impact Tests; S-N test DIN 50100; ILSS .In 1870, the first testing machines were developed by the Mannheim Machine Factory (MFL); In the years that followed, the company became known worldwide under the name Mohr & Federhaff, and in addition to tensile testing machines developed pendulum impact testers and torsion testing machines.; The company was acquired by Roell in 1986.Pendulum impact testers for impact test on plastics, including impact tests to ISO 179-1/ISO 179-2 and ASTM D6110. By playing this video, you agree to the use of cookies as well as to the transfer of data to YouTube in the USA. Additional data privacy notices.1. The Pendulum Impact Testers from Zwick are a HIT Important Characteristics Leading mechanical testing products manufacturer Zwick Roell Group’s HIT Pendulum Impact Testers are benchmark instruments for plastics manufacturers and processors Accuracy, dependability and ergonomic design are primary features of the HIT pendulum impact testers.

zwickroell impact tester

Sort by: [deleted] • 9 yr. ago. Inhumanity is decent more so just quantity while efukt is quality. yokohama11. • 9 yr. ago. (NSFW/NSFL): heavy-r.com. 45M subscribers in the .

zwick pendulum impact tester|pendulum impact tester